Introduction

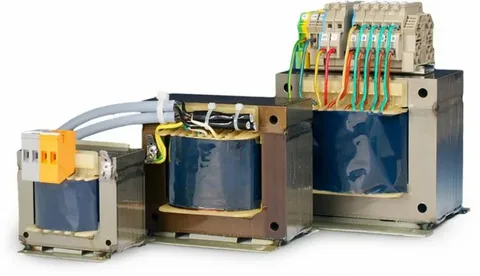

The US Industrial Control Transformer Market is expanding steadily as industries across manufacturing, energy, and automation adopt advanced electrical control systems. Industrial control transformers play a crucial role in supplying stable voltage to control devices such as relays, solenoids, and timers, ensuring safe and consistent operation of machinery. With the rise of industrial automation, robotics, and renewable energy infrastructure, the demand for reliable and efficient control transformers in the United States has grown significantly.

Market Drivers

The primary drivers of the US Industrial Control Transformer Market include the growth of industrial automation, modernization of manufacturing facilities, and expansion of renewable energy projects. Increasing adoption of process automation and digital control systems in industries such as automotive, oil & gas, and chemical processing is fueling market demand. The push toward Industry 4.0 and smart manufacturing has also heightened the need for precise and stable control power systems. Additionally, growing infrastructure investments and expansion of the power sector continue to support market growth.

Market Challenges

The market faces challenges such as the volatility of raw material prices—particularly copper and steel—which directly impact manufacturing costs. The presence of low-cost alternatives and imported products also puts pressure on domestic manufacturers. Moreover, high installation and maintenance costs, combined with the need for technical expertise in design and configuration, can restrain adoption among small-scale industries. However, ongoing investments in automation and safety enhancements continue to offset these challenges.

Market Opportunities

Emerging opportunities in the US Industrial Control Transformer Market stem from advancements in energy-efficient transformer designs and integration with digital monitoring systems. As industries transition toward smart grids and automated facilities, demand for intelligent transformers with remote monitoring and fault-detection capabilities is rising. Growth in sectors such as renewable energy, electric vehicles, and industrial robotics presents additional potential for control transformer deployment. Furthermore, federal initiatives promoting industrial energy efficiency create favorable conditions for technological innovation and market expansion.

Regional Insights

The Midwest and Southern regions of the US dominate the industrial control transformer market due to their concentration of manufacturing and heavy industrial activities. States like Texas, Ohio, and Michigan are key markets, driven by automotive, oil & gas, and metal processing industries. The West Coast, particularly California, is witnessing growing demand from renewable energy projects and automation-focused tech industries. Meanwhile, the Northeastern region is seeing gradual adoption in power distribution, utilities, and public infrastructure upgrades.

Future Outlook

The US Industrial Control Transformer Market is expected to experience sustained growth over the next decade, supported by increasing automation, modernization of grid infrastructure, and electrification of industrial operations. The integration of IoT-enabled monitoring, smart diagnostics, and eco-efficient materials will further enhance performance and reliability. As industries continue to emphasize safety, energy efficiency, and operational uptime, control transformers will remain a vital component of industrial electrical systems.

Conclusion

The US Industrial Control Transformer Market plays an essential role in powering the automation era. By delivering stable voltage for control applications, these transformers ensure reliability, safety, and efficiency across multiple industries. With technological innovation and increased investment in industrial automation, the market is poised for a future defined by smart, connected, and energy-efficient transformer solutions.